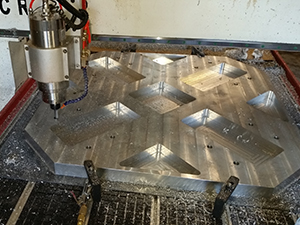

NC Machining

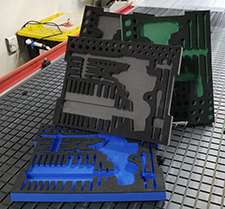

RCR Design provides custom machining for a wide range of industries. Our comprehensive machining processes includes, milling, drilling, boring, threading, profiling, and reaming.

Our machining capabilities can achieve tolerances of ±.005", verified through a number of quality control measures.

To learn more about all of our CNC machining capabilities please Contact Us directly or Request a Quote.

CNC Machining Capabilities

|

General Capabilities:

- 2D & 3D Machining from Small to Large Sized Components.

- 4th Axis Machining.

- Turning.

- Machining Processes:

- Milling

- Drilling

- Boring

- Tapping

- Counterboring

- Countersinking

- Pocketing

- Profiling

- Reaming

- Turning,Parting/Cutting

- Facing

|

CNC Router:

- Milling Length: Up to 96 in

- Milling Width: Up to 48 in

- Handles 4' X 8' Sheet Stock

- Milling Height: 12 inch Gantry

- 600 IPM Feed Rate

- 24000 RPM 10HP ATC Spindle

- Vacuum Table

- Kurt Vises

- Machine Tolerances: ± .005

- Production Volume:

- Prototype to Production

- Standard Leadtime:

- 1 to 3 weeks

- Expedited Service Available

|

|

- Equipment:

- Vertical Machining Centers

- Equipment Capabilities:

- CNC Control Capabilities

Machine Axis Capabillities:

3 & 4 Axis Machining

Inspection:

Set Up, In-Process & Final

Quality Control Capabilities:

- Digital Height Gages,

- Thread Gages,

- Measuring Equipment

- Fixturing:

- In-House Fixturing & Tooling

- Vacuum Table & Kurt Vises

|

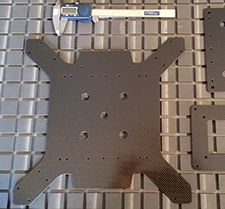

- Materials:

- (Non-Ferrous Metals)

- Aluminum

Brass - Bronze

Copper

- (Plastic Polymers)

- Nylon

Delrin

Acrylic

G-10 Phenolic

UHMW

Polycarbonate - Polyetheretherketone

Polyethylene

Polypropylene

Polystyrene

PTFE

PVC

(Wood)

Soft Wood

Hard wood

Wood Composites

|

|